Split Set® accessories

Split Set® bearing domed plates

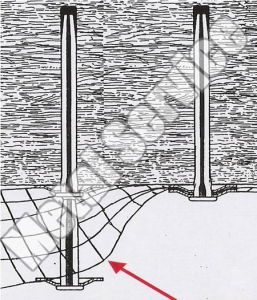

The METAL SERVICE Split Set stabilizer is composed of two parts, the tube, and the bearing domed plate which is an integral part of the system.

Plate loading is generated immediately. No torquing or retorquing.

- combi plate 400x280x2mm (with plate 150×150)

- spider plate

- W plate 750x220x2mm

All METAL SERVICE plates are supplied black steel or galvanized.

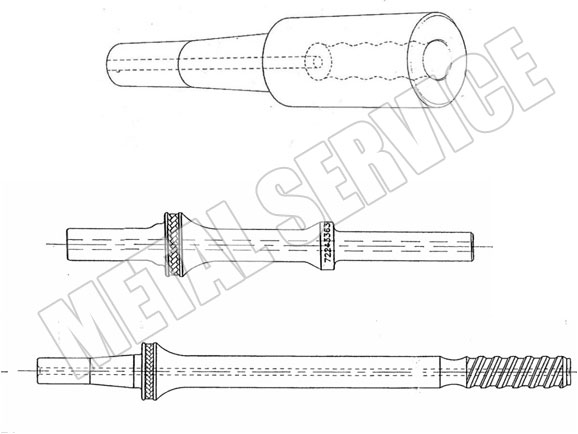

Split Set® driver tools

The Split Set bolt is driven into a slightly smaller hole using same percussion drill which made the hole. At METAL SERVICE, various male and female driver tools are available to fit all drifters, pneumatic or hydraulic hammers, and all Split Set models. METAL SERVICE is supplying typical long- nose or short nose SS39 drivers, rope- threaded drivers, covering the mining industry or civil construction needs.

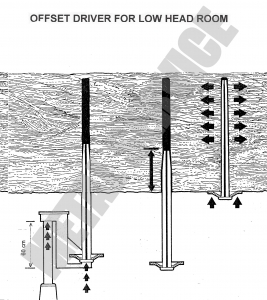

Offset Driver

In narrow veins, rock bolting is sometimes not easy. Miners need to optimize the bolt installation in keeping reliable rock support capacity.

By using the METAL SERVICE Offset Driver with Jackdrill to install Split Set stabilizers (model SS39) , you can save 60 to 70 cm in low head room or narrow veins situations. The Offset Driver will help to keep the Split Set alignment.

Split Set® utility hangers

Split Set utility hangers (45 and 60 cm) are used for easy screen and mesh installation to stabilize highwalls on surface, shafts walls or any underground cavity where skin support is needed to avoid rock falls. The plate loading will firmly apply the mesh against the rock. The Split Set utility hanger supplied by METAL SERVICE can be installed inside longer Split Set already used for rock support. No need to drill a new hole. Short Split Set utility hangers are not intended to rock support. These shorts units can also be used to fix :

- ventilation tubes, water pipes

- cables…

Eye bolts

Eye bolts are accessories commonly used to attach cables or ropes.

Eye bolts diameters available at METAL SERVICE: Ø 16 (thread M18) / Ø 20 (M22) / Ø 22 (M24) / Ø 24(M25).

Eye bolt length: 600 à 2100 mm / thread 150 mm.

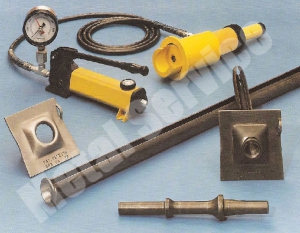

Pull tester device

Pull tests help to verify the Split Set effectiveness after installation. They are normally performed with a pull tester assembly supplied by METAL SERVICE. Pull tests are not destructive and the bolt does not need any further maintenance after the test is done. Compared to other conventional bolts, the Split Set will not break and the measurement will give the frictional performance, also called the pull-out strength, or slip load.

Split Set conforms to ground shifts. Days or weeks later a typical Split Set stabilizer is tighter than ever. The pull tester material consists of two parts: a mechanical assembly (claw, housing, spacer, nut and spindle) and a hydraulic unit (cylinder, pump, gage and hose). The general principles and operational method concerning bolt tests are specified in the AFTES GT6R4F1 (French tunneling and underground space association).